Could X-ray become the product inspection standard?

When you hear the word ‘x-ray’, your first thoughts will likely be the medical use of it, such as scans of broken bones. However, x-ray is also utilised in the manufacturing industry as an effective form of product inspection.

In the current market, there is little discussion around x-ray compared to more traditional inspection forms, such as metal detection or checkweighing. It’s still a relatively new concept, too – we only introduced our first x-ray system in 2019. There are also many myths around x-ray safety that might deter some people from considering it.

Despite this, there is lots of potential in x-ray inspection’s ability to identify a wide range of contaminants. By using it, manufacturers strengthen their quality control processes and improve the calibre of their output consistently. With such capacity, could x-ray become the product inspection standard?

Below, we explore that question, looking at the benefits x-ray bring and busting some of the myths around it.

- Why is x-ray beneficial in product inspection?

- What are the myths around x-ray?

- What to consider before introducing an x-ray system to your plant

Why is x-ray beneficial in product inspection?

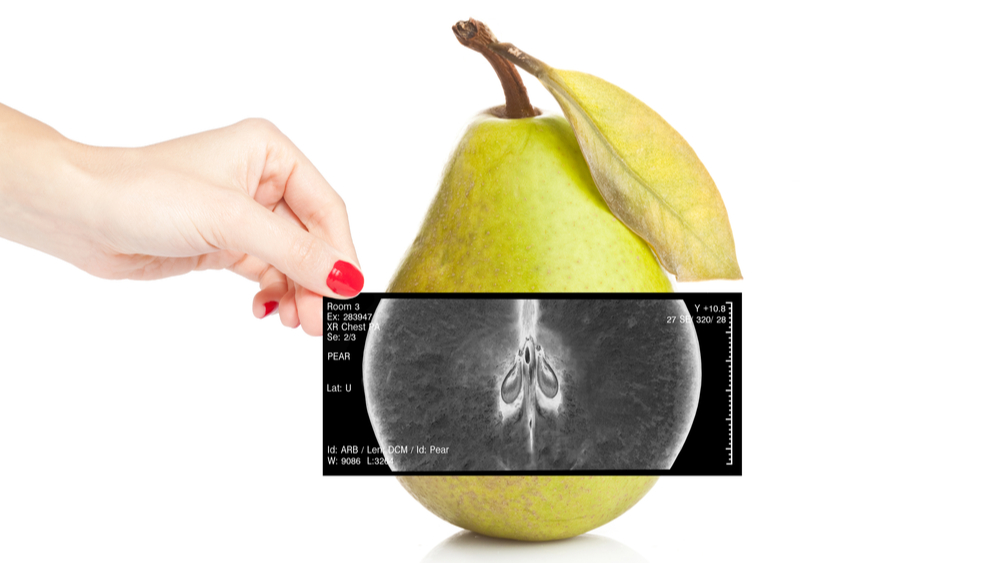

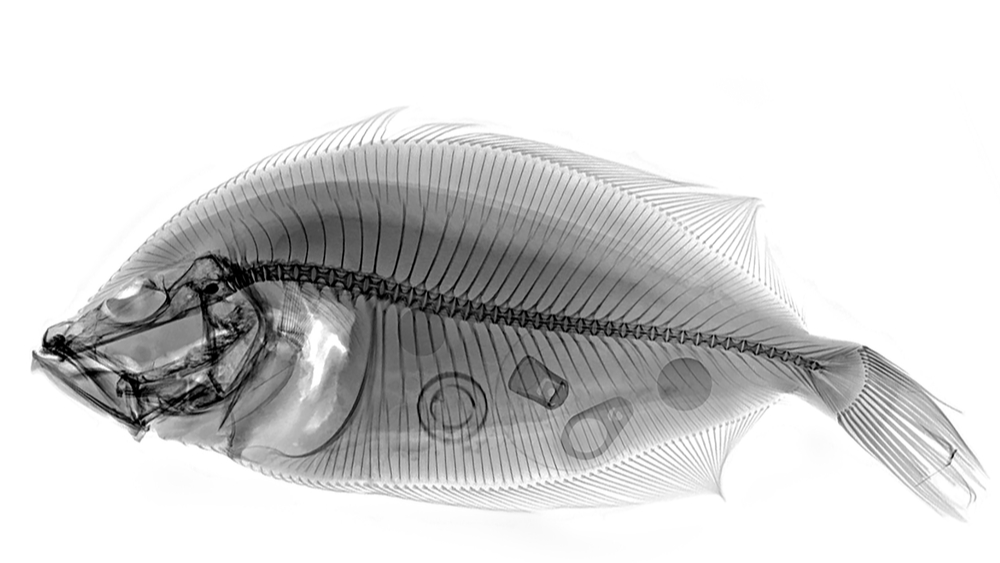

X-ray is one of the most comprehensive forms of product inspection, offering manufacturers valuable insight into their output. It is also compatible with numerous products, including fresh produce, meat, frozen food, ready meals, pharmaceutical and so on.

Using an x-ray, you identify a range of contaminants that could impact your product quality. These include metal, stone, bone, plastic, glass and produce clumps, to name just a few. It is worth noting that x-ray will not identify low-density contaminants such as paper and insects. Still, it is used alongside other inspection protocols to strengthen your overall quality control.

X-ray is utilised at various stages of your production line, though it is most commonly used in-line or as a final check before the items reach the hands of your customers. It is even be used on packaged products.

With its ability to work on different types of products and find contamination across the production process, x-ray enables you to incorporate a higher level of inspection into your factory. This has many knock-on effects.

Firstly, it will help you to raise your compliance standards. Many industries, particularly the food industry, have requirements that you need to meet as a reputable manufacturer to protect consumers. Quality control forms part of these requirements, so introducing a practical solution like x-ray will help you comply with guidelines. This will allow you to build on your reputation as a trusted business and prevent any ramifications from non-compliance.

By identifying a wide range of contaminants, you improve customer safety. Contaminants like metal and bone pose serious health hazards to consumers, and if your business is embroiled in such a scandal, it causes reputational damage. It also increases the likelihood of customer complaints, product recalls or legal consequences.

It will improve your output quality, too. With this, you enjoy better customer satisfaction which leads to more sales and increased profit.

Finally, an x-ray helps you to finetune your production lines. Most x-ray systems will include data logging and analysis, so you record any issues that arise. This will help you identify the cause of contamination, whether from within your plant or a supplier fault. You then fix the problem to prevent it from reoccurring and improving quality assurance.

What are the myths around x-ray?

Although x-ray does boast many benefits as a form of inspection, myths still exist that may deter some people from embracing it. One of the main fears is the impact of radiation, which some manufacturers believe could compromise their product and pose harm to staff and customers.

If you implement an x-ray system into your factory, you will need an appointed Radiation Protection Supervisor. This individual will be thoroughly trained and responsible for compliance with ionising radiations regulations. You’ll also need an external Radiation Protection Advisor who will support your supervisor in their role. By having these resources present, you ensure that your x-ray system is used correctly at all times, minimising any risk to your production line and staff.

All x-ray machines on the market will also come with safety features, such as enclosed cabinet systems that meet compliance guidelines and keep your staff safe.

X-ray radiation is not the same as a radioactive source, which some people may confuse. This means there is no danger to your plant. When you turn off the power to your system, it will immediately stop x-ray generation, so you do not need to worry about radiation when you are not using it.

X-rays also aren’t absorbed by food, so your products will not be compromised. An x-ray will pass through food for less than a second during inspection, with a minimal level of radiation. A 1997 study by the World Health Organization (WHO) confirmed that radiation levels don’t affect a food’s safety or nutritional value. This should offer additional peace of mind about the safety of x-ray when using it as a production inspection tool.

What to consider before introducing an x-ray system to your plant

Although x-ray is a perfectly safe option for your product inspection and provides a comprehensive review of your output, there are still considerations to make before you commit to installing one in your plant.

When implementing adequate quality control processes into your manufacturing processes, you need to ensure that the approach you take is fit for your unique requirements. This means considering the product you are creating and the possible issues it could be affected by, including what kind of contamination it could experience. From here, you plan the best solution and introduce it into your lines. While x-ray is suitable for most industrial applications, some manufacturers may need to consider alternative options to address their needs better.

You’ll also want to find a machine that slots into your existing processes and lines. This will make it easier and quicker to incorporate x-ray into your plant without having to alter your operations drastically. This could include finding a model that fits in with your conveyor system. Combined checkweigher and x-ray options offer conjoined and enhanced product inspection.

To get the most from your x-ray system, you need to make sure you use it properly. This means using at the correct stages of production, with properly trained staff that operate it efficiently. As x-ray machines are often an investment, this enables you to prolong their lives and access better results, offering you better ROI.

Conclusion

There is no denying that x-ray offers a great deal of potential when it comes to product inspection. Although a relatively new concept in the manufacturing industry, and one that is still liable to misinformation, it substantially impacts and improves results.

By utilising x-ray, plants unlock improved quality, customer safety and compliance. Such systems provide a great return on investment for manufacturers, saving costs in the way of product recalls and lost sales.

Only time will tell if more manufacturers adopt x-ray into their processes, leading it to become the industry standard. However, if they do, it could offer sizeable advantages for manufacturers and consumers alike.

If you want to find out more about the role of x-ray in your product inspection, we will talk you through how it works and its compatibility with your requirements. Our downloadable x-ray webinar may also answer any queries you have.

We provide solutions for your plant with our YX20 checkweigher and x-ray combi. Our team will commission the system for your existing production lines for efficient installation. We work with you to train your staff, including your Radiation Protection Supervisor and recommend a Radiation Protection Advisor.

Get in touch today to find out more.