How does a multihead weigher work?

Yamato is known for providing world-class weighing solutions, with our first multihead weigher with load cells developed in 1979. Since then, multihead weighers have become a crucial part of production lines, offering the ability to weigh a wide variety of product types.

If you are new to weighing in your sector or are simply looking to invest in the best solution for your requirements, it’s essential to understand how one works and the different characteristics that can make them compatible with your products.

This guide explores how multihead weighers work on a technical basis, why they’re used and what to consider when identifying one that suits your production needs.

- How does a multihead weigher work?

- Why use a multihead weigher?

- What to consider when choosing a multihead weigher

- Where to find the right weigher for you

How does a multihead weigher work?

A multihead weigher works by taking a bulk product (usually your raw materials) and splitting it into smaller volumes, based on pre-defined limits you programme into the software.

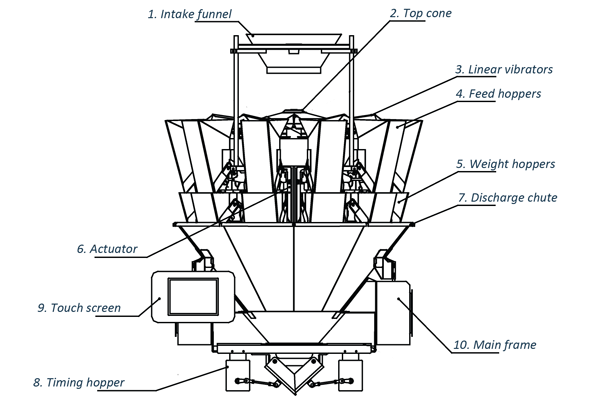

The weigher will have several features, including weigh buckets, feed buckets, infeed funnel, feeder pans, top cone, collating chute and collating funnel.

The process starts with materials fed into the infeed funnel, often by a conveyor belt or bucket elevator. The top cone and feed pans, usually through vibration or rotation, will then move the product into the weigh buckets, each of which has a load cell to constantly monitor the amount of product contained. The weigher will be designed to ensure an even distribution of product.

Depending on the target weight and other programmed specifications, the software will determine the best combination of weights to meet the correct total amount. It will then distribute the product accordingly, with hoppers used to refill a bucket as soon as it becomes empty, creating an continuous cycle.

Why use a multihead weigher?

The main advantages of using a multihead are speed and accuracy. The use of load cells in the system allows you to process bulk products while still allowing you to adhere to your weight targets precisely. The heads of the weigher are constantly refilling, which means you are able to access higher speeds than you would with a manual weigher and automate the process.

Due to the various features that may be implemented in a multihead weigher, getting a tailored solution that suits your product type is achievable. This means it can be used across sectors and address a wide range of production challenges.

Finally, most multihead weighers will work alongside other equipment, such as checkweighers and product inspection systems. A conveyor system will feed product from one area to the next, with minimal manual intervention. This improves quality and accuracy across your production line, creating an output that meets specifications and customer expectations every time.

What to consider when choosing a multihead weigher

You should consider many factors when selecting a multihead weigher for your plant. Each system incorporates unique features to make them more compatible with specific product types or objectives. We’ve listed the most significant below.

-

Number of heads

A multihead weigher may include many weigh buckets (known as heads), usually 10 to 32+. The more heads you have, the faster the systems works out the best combination to meet the total weight target. This also increases the accuracy of weighed portions in one go.

If you are trying to process large amounts of bulk product quickly, having more weigh heads will increase speed without losing accuracy.

-

Surface types

Depending on the consistency of the product you are processing, there may be additional features required to enable it to be weighed efficiently.

Dimpled surfaces may need to be added to weigh buckets to make it easier for sticky products (such as confectionery and fruit) to move through the production line. Smoother surfaces will work best for dry products.

-

Vibration

Alongside the surface type, the amplitude and duration of vibration used to distribute the product will need to adjust to the materials you are using.

Sticky products will require more vibration to encourage the product to travel. As dry products tend to be more free-flowing, minimal vibration is required to move them. This also accommodates the careful handling of delicate products.

Consider the products you will be using in your multihead, as this will enable you to ensure you have the right features for maximum compatibility and results.

-

Bucket size and shape

If you are processing bulky products, you will want a weigher with bigger buckets as it enables you to weigh more in one period. This is also applicable if you need to fill larger containers.

Alongside the size of your weigh buckets, you need to consider the shape. This will largely depend on your requirements.

Polygon-shaped buckets or rounded corners are easier to clean, making them useful for sticky substances that require cleaning between batches. This may also help you to achieve specific hygiene targets in your plant. For drier products, standard buckets should suffice.

-

IP rating

IP ratings classify to what extent a machine’s mechanical and electrical components are resilient against water, dust, and other intrusions. If you are working with sticky products, or you need to regularly clean your weigher to meet compliance standards, you need to ensure the IP rating is sufficient.

An IP rating will typically have two numbers – the first referring to the protection against dust or solid objects and the second referring to protection from liquids. In both cases, the higher the number, the more durable that system is.

You typically do not want to go any lower than an IP54 rating if working with food (and even that will be insufficient for many environments). If you aren’t working with sticky substances but need to wash down equipment, you will probably need a minimum of IP56.

For products with a liquid consistency, requiring in-depth cleaning between uses or harsher environments (such as frozen foods, fresh produce and so on), you will need a much higher IP rating – such as an IP65, 66 or 67. This will enable you to process the materials you need without compromising the longevity or performance of the weigher.

-

Maximum weighing range

A point of comparison between multihead weighers will be the maximum capacity it can handle at any one time. Some machines will be designed to hold larger volumes, and factors like the size and number of heads influence this.

If you work with bulky produce or need to process significant amounts of product in a single-use, you will want a higher weighing range. You will need to account for the maximum volume that can be weighed, the weight per load cell and the range available in a single discharge, as this will inform you how quickly you can expect to process your output to meet targets.

-

Speed

Speed is another feature you will use to identify the best weigher for you. The faster the weigher can process output, the quicker your turnaround times are. This will be particularly beneficial when working with extensive volumes.

To determine the speed, review the weighs per minute of any machine you look at. The higher this is, the faster it will operate.

When working with fragile products, you may need to compromise on speed to enable delicate handling. The key is understanding your materials and ensuring any weigher caters to their unique requirements.

-

Footprint

Depending on the size of your plant and the space available in your production line, you may require a multihead with a smaller footprint. This enables you to access the solution you need while fitting it into your existing environment.

If you are looking for a smaller weigher, you must choose one that offers excellent results, including speed, accuracy and compatibility. This will allow you to maximise performance despite space limitations.

-

Additional extras

Beyond what we have already disclosed, several optional extras could be added into a multihead weigher. They may not all be necessary, but depending on the aims of your production line, they can offer valuable support.

Examples of such extras include:

- Weighers with reduced giveaway/waste to help reduce costs and meet sustainability goals

- Usability features, such as touch screens and pre-set programming

- Data collection, enabling you to analyse performance and react to issues in real-time

- Automatic feeding control

Some of these features may be included as standard in systems. The most crucial element is ensuring that you select a machine compatible with your products and able to achieve your goals. However, if you’re torn between choices, these additions can guide your decision.

-

Price

As with any manufacturing equipment, multihead weighers will vary in price between suppliers and models. If you have a set budget for your plant, you will want to find a weigher that suits your needs at the best price.

Many factors will influence the cost of the multihead weigher, including the number of heads and weighing capacity, speed, IP rating, overall size and any additional extras you might wish to include. It is up to you how much you are willing to invest and what you can get for your money.

It is worth noting that, even if a multihead weigher is costly, buying an effective one can improve profitability by driving quality, reducing production issues and speeding up processes. This generates an excellent return on investment that makes the price worthwhile.

Where to find the right weigher for you

The first step to finding a suitable multihead weigher for you is understanding your requirements. Once you have identified these, you will research the market for a compatible system.

At Yamato, we offer a broad range of multihead weighers to address almost every product type and need. We’ve listed the range of products we currently sell with a brief explanation of the benefits each can bring.

- Omega Series – our world-class multihead weigher, with up to 32 heads for increased productivity and an IP67 rating

- Epsilon – a mid-range solution offering high performance at an affordable price, with an IP66 rating

- Alpha Series – offering an increased performance-price ratio, including compact, waterproof and twin models

- Sigma – an accurate weigher that reduces waste and increases up-time

Alongside any multihead weigher you purchase from us, we provide invaluable staff training that encourages your workforce to process output correctly and efficiently. We will also commission machinery into your plant and tailor them to meet your bespoke needs.

We offer long-term service contracts and support with spare parts management solutions that will increase the lifespan of your weigher and keep it working in optimal condition for maximum results.

To speak to a member of the team about your multihead weighing need and find the perfect package for your plant, get in touch with us today.