Reduce product giveaway with actuator repair

Although integrity and reliability is intrinsic to what we do, sometimes parts repair and replacement may be needed during a weighing machine’s life due to general wear and tear or other external influences.

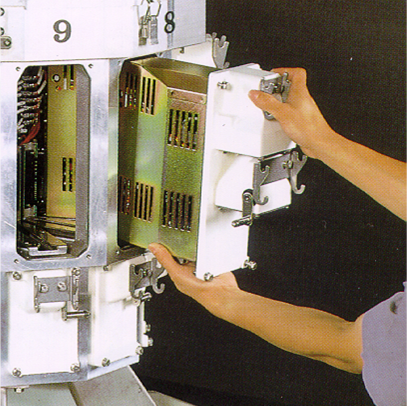

Actuators are essential to your multihead weighing machine’s performance. They contain the ‘load cell’ or ‘weighing scale’ of the machine, and the motors and levers which control the movements of the buckets. So, keeping them in tip top condition is vital.

In this blog we will tell you about:

- Zero drift error

- Actuator failure

- How to tell if your actuators need repairing

- Why repair your actuators

- Why choose genuine Yamato spares for actuator repairs

Zero drift error

You need to be on the look out for a number of issues that could affect performance. The main one is a zero drift error. A zero drift error reading can have a serious and detrimental impact upon production.

This is where the zero value of a re calibrated actuator drifts, showing a weight which does not exist. If you don’t address zero drift error it can get worse over time, affecting accuracy and resulting in overweight packs and expensive product giveaway.

The risk of producing underweight packs is also increased. Such packs are illegal under certain weights and measures legislation and falling foul of the law could make a serious dent in your reputation.

Actuator failure

Actuator failures can have a detrimental impact upon weighing performance, reducing the number of heads available for weighing and potentially reducing your production output.

If, in the event of a general actuator failure, where weigh heads are inhibited as part of the machine’s fail-safe action and the actuator repair has been neglected, production levels, as well as the speed and accuracy of your machine, can be significantly reduced.

How do I know if my actuators need repairing?

Zero drift is the main repair indicator. If your machine exhibits zero drift it will display weights which are inaccurate which could have a severe detrimental impact upon production.

A zero drift error may become apparent after removing, cleaning and replacing the buckets, then re-zeroing the actuator in the manual operation screen. Watch the display for a change in weight. Any movement beyond +/- 0.5g over a ten-minute period means your machine will definitely require the attention of a Yamato engineer. The greater the margin of error, the greater the weight shift will be over a shorter period of time.

Other indicators that your actuators could need attention may include:

- Bent lever(s)

- Load cell strain

- Excess movement of drive arms and levers.

- Unable to “Original point” a motor when the bucket has been removed

Why repair actuator units?

Repairing actuators is vital to guarantee optimised and accurate production at all times. It also improves the longevity of your machine.

Actuator repair ensures:

- All packs are accurately weighed to ensure compliance with Weights and Measures regulations as required by Trading Standards

- Product giveaway and waste is reduced – an important consideration in the current economic climate

- Optimum production levels and speed at all times

Why choose genuine Yamato spare parts for actuator repairs?

Only Yamato can supply Yamato Scale Dataweigh guaranteed parts. These parts are genuine, certified and specific to your machine.

It is important to ensure that cost-saving measures do not compromise the quality, performance and longevity of your machine for the sake of short-term gain. Using non-Yamato load cells can increase the likelihood of breakdowns as components are often of an inferior quality. These are far less accurate and are often constructed using cheaper components which are significantly less hard wearing than Yamato Genuine Parts.

All machine repairs are carried out by dedicated and experienced Yamato engineers who have undertaken rigorous Yamato training to equip them with unparalleled knowledge of Yamato’s range of weighing machines.

To avoid long downtimes when problems occur, we offer a service exchange. A Yamato engineer should always be called because their knowledge and experience will ensure that any issues are resolved promptly and professionally; whereas a general technician may only compound the problem – increasing downtime and ultimately costs.