The risks of using pirate spares on your production line equipment

Consumer piracy is big business. Pirate and counterfeit parts flowing out of the Far East costs the industry billions of pounds every year. But it’s not just the automobile and consumer electronic sectors that are suffering, there’s an increasing market for non-genuine parts for weighing machines, multihead weighers and checkweighers as well.

We’ve all done it. We have something we want to fix or replace, whether it’s a car or a TV, and want to do it as cheaply as possible. We have a look on the web and find a pattern part.

The low price should warn us it’s a cheap and nasty imitation. It doesn’t fit properly, so we end up bodging the job, leading either to failure and the need for another replacement part or we end up buying an original part, leaving us more out of pocket.

Consumer piracy is big business. Pirate and counterfeit parts flowing out of the Far East costs the industry billions of pounds every year. But it’s not just the automobile and consumer electronic sectors that are suffering, there’s an increasing market for non-genuine parts for weighing machines, multihead weighers and checkweighers as well.

Under-pressure plant managers often choose cheaper pirate parts, but there are very good reasons why this practice should be avoided as an example of false economy.

There are many risks associated with buying pattern or pirate parts, relating to:

- R&D

- Standards

- Costs

- Safety

R & D

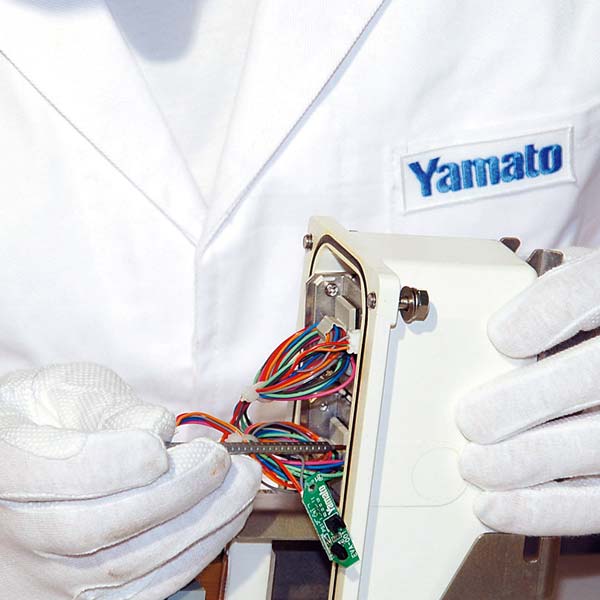

Machinery manufacturers invest millions each year in research and development. Every component undergoes exhaustive testing in both laboratory and field-based trials to ensure the materials, manufacturing processes and quality control are of the highest possible standard.

Clearly there’s a cost attached to these activities making spare parts developed in this way appear expensive. There is, therefore, a temptation for maintenance engineering managers to use cheaper alternatives when planning routine service programmes in their plants. This is frustrating for original equipment manufacturers (OEMs) that have to deal with failures and warranty issues due to the use of non-genuine or pirate parts.

Many parts – such as actuators used in automatic and semi-automatic checkweighers and table-top weighers – are sophisticated pieces of electronic equipment. Ultimately, many companies that use pirate parts will end up paying twice for service and repairs, and potentially lengthy shutdowns of their food processing and packaging lines, which is a false economy.

Standards

If you install a pirate part there’s no guarantee that the component, which may have minute differences to the existing genuine parts, will run effectively indefinitely. Failure of the pirate part will involve consequential damage to connected components resulting in wider damage and associated costs to your business.

Pirate parts haven’t been tested to the same exacting standards as genuine parts; they might look the same, but their origin and quality is unknown and therefore ‘suspect’.

Genuine spare parts manufactured by OEMs are backed by intensive research and stringent quality control, guaranteed to deliver value and assure reliability and precision over the long run.

Counterfeiters cut corners on technical studies and quality control to slash costs. Appearances can be deceiving. These look-alike parts are often poorly finished and made to a poorer standard, using low quality materials offering less durability.

With genuine parts, you can manage obsolescence and take advantage of the latest design enhancements available during the life of equipment such as checkweighers, multihead weighers and metal detectors. The risks of incompatibility are greatly increased with the use of pirate parts.

Costs

When choosing between an original component or a corresponding copy product, you need to assess both the costs of the parts and the risks associated with their use. These costs are not only those related to the individual part but also include the labour for the interruption to service, and the machine downtime which can be caused by premature failure.

The fact that a counterfeit part fits doesn’t mean it is manufactured to the same standard as a genuine part. Copy parts can be poor quality, unreliable and potentially dangerous, so it’s important to be aware of the impact that fitting pirate parts may have. In the event of a system failure – or, worst-case scenario, an accident – the ultimate responsibility lies with the service and repair engineer rather than the incorrectly-chosen product.

Genuine parts work better and longer, reducing costs and downtime due to breakdown or maintenance.

Safety

Faulty or out-of-spec generic parts can compromise machinery and lead to safety concerns for the operators. Bad or poor performing electrical parts can lead to control failure, open circuits, fire hazards and other potentially dangerous operating conditions.

By only stocking and using reliable OEM-warranted parts, the overall safety of your processing facilities is increased and there’s a contribution to positive risk management for your workers.

No matter how good the quality of the part, there’s usually a price level that can’t be exceeded. The use of non-genuine parts is more likely where your machine is of low capital cost. However, it’s in your interest to install parts that are fit for purpose to ensure that the equipment works efficiently, safely and reliably. The cost of the spare is just part of the overall cost of repair, and it takes a technician just as long to replace a non-genuine as a genuine spare part.

Using genuine parts also helps to reduce the possibility of repetitive failure. Doing so also reduces the production downtime that can damage the reputation of the end user in terms of its ability to deliver its products reliably.

Using genuine parts means it’s less likely that there’ll be subsequent failure, ultimately reducing the inventory costs for holding spares and improving your repair cycle forecast.

You only need to store parts that require frequent replacement. Genuine parts can reliably be ordered online and dispatched quickly, thereby reducing the need to invest in stock and downtime caused by failure and the wait for repairs.

All in all, the risks of using pirate parts outweigh the benefits. You should always choose genuine parts for repairing your Yamato Dataweigh equipment.