What does the food industry use x-ray detection for?

Manufacturers face many barriers in their bid for the utmost quality. In today’s challenging environment, specific requirements must be met to meet customer expectations, including supermarket compliance standards and safety regulations.

A large part of ensuring high quality is uncovering the issues that may compromise output. This requires excellent quality control and product inspection.

There are many forms of product inspection on the market today, but x-ray is increasingly becoming the industry standard due to its in-depth coverage. It does have several roles in a plant, enabling you to fulfil various tasks and offer consistent quality.

We explore the primary purposes of x-ray detection in the food industry and what can be achieved through it.

What do manufacturers use x-ray detection for?

-

Uncover contamination

Many forms of contamination are detectable by x-ray, including stone, metal, glass, rubber, some plastics, bones, and produce clumps. It won’t catch every contaminant, but it is by far the most extensive single form of detection on the market.

For manufacturers who want to inspect their food products thoroughly, x-ray is the obvious choice. This is especially key when working with materials susceptible to a broader range of contamination, such as meat or fresh produce, enabling better safeguarding.

-

Find broken seals

A common issue that affects manufacturers is broken seals in their packaging, which may stem from damage, faults or extruding materials. A damaged seal leaves a product liable to other issues, such as leakages, spoilage and contamination. Receiving a packaged product with a broken seal is also likely to deter customers, especially if they fear the product has been compromised.

An x-ray system can analyse packaged products and enable you to uncover broken seals, using low photon energy to review film, foil and Tyvek seals. As a result, you can eliminate any further issues before they happen and maintain customer expectations.

-

Find broken glass containers

The nature of x-ray means that it can analyse products in containers, including glass. Glass containers are subject to breaking, particularly during the packing and transportation processes.

If glass packaging were to break, it could have hazardous ramifications for customer safety. A manufacturer will want to do everything possible to avoid it. Using x-ray inspection can identify glass contamination from container breakages to remove the danger before it reaches your customers.

-

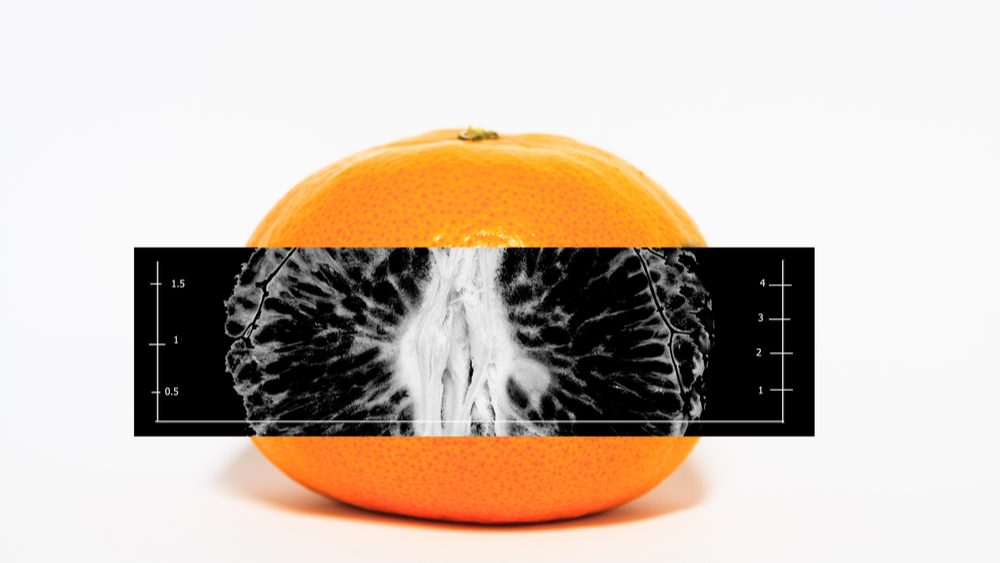

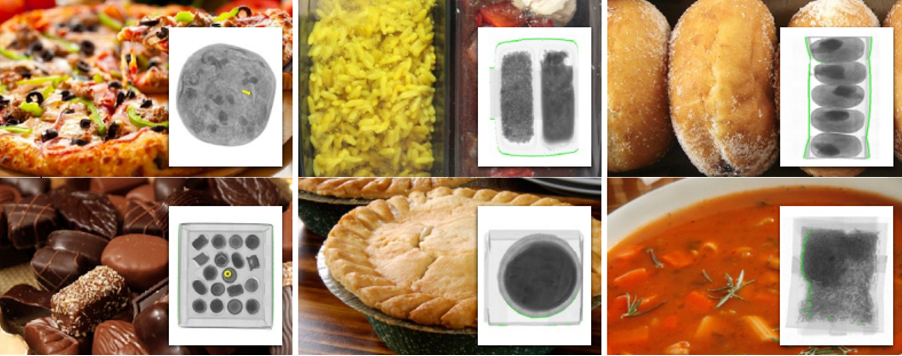

Distribution of ingredients

X-ray is not only helpful in finding contaminants in a product. It can be used to analyse the ingredients there and ensure they are distributed appropriately.

There are many instances where this may happen, including pizza toppings, salad toppings, boxes of chocolates, product fillings (such as in pies and pastries) and layered products (such as pasta or yoghurts).

By using x-ray detection, you are able to review the distribution of contents and check they are placed sufficiently. This offers a premium experience to the customer and drastically impact customer satisfaction. It is also instrumental in meeting the set specifications of projects if an ingredient ratio has been pre-agreed.

It’s also an excellent cost-saving measure to avoid using too many ingredients on single products.

On the other hand, it also uncovers missing products that may not be included in the packaging so they can be redistributed.

-

Improve presentation

In a similar vein to ingredient distribution, x-ray is utilised to deliver perfect presentation across output. This is particularly warranted when manufacturing luxury products that must meet precise quality and aesthetic requirements.

One example of using x-ray to review the appearance of a product is in the dairy industry, where x-ray may be used to check the distribution of cheese holes that affect a customer’s desire to choose the product and how matured the cheese is.

Similarly, x-ray is used for packaging items to ensure that food sits in the correct position of its packet – for example, easter eggs, where the product needs to sit centrally, or gift hampers.

-

Checking liquid levels

When working with fully or partially liquid products, x-ray checks the fill levels of containers and ensure the correct amount of liquid is included in each.

The main benefit of using x-ray is to avoid overfills, where too much product is placed in a container. Therefore, waste is reduced and costs better managed, with only the specified volume of liquid used per product.

-

Inspecting products in rigid containers

Finally, x-ray is a valuable end-of-line control point for packaging products, including those in rigid containers, glass-in-glass packaging or ring-pull packets.

The product is analysed through packaging by positioning beams correctly (and using multiple beams for reliability), offering a final check before it leaves the plant.

This is another example of the breadth of x-ray inspection, enabling quality control on finalised products in a way other inspection systems cannot.

The benefits of x-ray inspection

Alongside the wide range of purposes listed above, including even complex production issues, there are many additional benefits to x-ray inspection. We have listed the most significant below.

Improving quality control

Manufacturers must follow stringent quality control in the advanced age of health and safety and heightened attitudes to safety following the coronavirus pandemic. X-ray offers this at an extensive level.

Using x-ray detection, you can protect your output against a wide range of contaminants and other issues that could dissatisfy or even harm customers. It will also support you in addressing the many compliance standards in the food industry, including HACCP, ISO 22000, British Retail Consortium, codes of conduct and more.

Many UK supermarkets now request advanced quality control as a prerequisite for any partners. By utilising x-ray to enhance yours, you will generate increased opportunities.

Driving customer sentiment and brand reputation

By meeting industry regulations and improving customer safety, you build a reputation as a trusted and reliable food manufacturer. This enables you to maintain and grow sales.

Part of this comes from reducing the danger of customer complaints, legal action or other unfavourable attention that may stem from a hazard in your product.

X-ray is also used for the finer details, such as product presentation, which elevates the experience offered to customers and consistently meets their expectations.

Reduce waste

Manufacturers are facing increased climate pressures. The government and customers are pushing sustainability, and all plants need to play their part to win over business and contribute to the global effort to protect the environment.

Product inspection has a role in this. You reduce product waste through effective quality control by ensuring more of your output meets your specification and does not need to be thrown away. It also prevents the need to re-run lines where anomalies have been identified too late, using additional energy and materials.

It will also improve product giveaway, which often leads to waste.

Cost management

Product inspection plays a crucial role in cost reduction. As already discussed, it reduces waste, which means you get the most from your supplies for cost-efficiency.

On top of this, x-ray detection diminishes the risk of costly product recalls stemming from contaminated products. The potential scale of this has recently been seen with Kinder’s widespread product recalls.

X-ray inspection will help support you in minimising the risks of such recalls to maintain profitability and reputation.

Safe to use

Despite some lingering myths, x-ray is a safe form of inspection for food.

Any x-ray system you buy comes equipped with safety features that reduce danger to customers and employees. You will also be required to appoint a Radiation Protection Supervisor within your plant and an external Radiation Protection Advisor to ensure you comply with radiation standards.

It’s essential to note that x-ray radiation is not radioactive and is not absorbed by food. Your products will be subject to minimal radiation, usually for less than a second. A 1997 study by the World Health Organization (WHO) confirmed that radiation levels do not affect a food’s safety or nutritional value – reinforcing that this is a safe form of quality control.

In summary

Due to the comprehensive coverage and ability to address a broad spectrum of problems, x-ray has a crucial role in the food industry. It offers a safe way to identify contamination, eliminate product flaws and enhance customer safety.

Using it effectively, you deliver consistently high quality across your output which builds a favourable reputation, grows sales and drives rewards. It also enables you to minimise costs and waste – a necessity in the current climate.

If you consider incorporating x-ray inspection into your production lines, Yamato’s YX20 x-ray system offers superior results and safeguards your products against a broad range of issues in real-time.

We work with you to appoint a Radiation Protection Advisor for your plant and provide practical staff training that ensures efficient processes.

Get in touch today to obtain a quote for your plant.