Why is x-ray the best choice for food inspection?

When processing food, a manufacturer’s key priorities are ensuring their products are safe for consumption whilst enabling customer satisfaction and meeting industry standards. Due to these requirements, product inspection and quality control practices are vital in ticking all the manufacturer’s boxes.

In order to guarantee consumer safety and satisfaction, a food processor needs to identify and remove any possible contaminants in their line, assure high quality and meet the expectations of their clients. However, it’s unfortunately easy to drop the ball and miss a potentially disastrous flaw in your product. With consumer behaviour changing to emphasise quality in their food purchases, this isn’t a mistake you can afford to make.

Taking a robust approach to product inspection will help you to reduce the risk of a sub-par product and the accompanying ramifications. This means having effective equipment that assists you in your mission – such as an X-ray inspection system.

X-ray is one of the most comprehensive forms of inspection manufacturers can access today. It’s also compatible with food products, despite some of the myths you may have heard, making it an ideal choice for a food processing line.

This blog explains how x-ray works in more detail and the benefits it could bring to your plant.

How does x-ray work in food inspection?

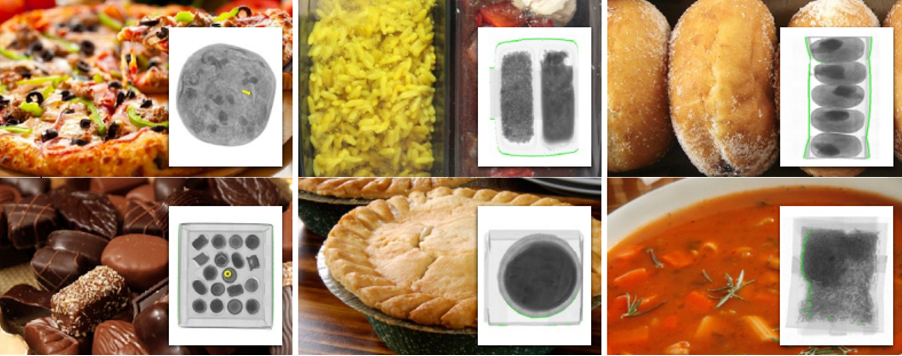

X-rays work by utilising high energy waves to penetrate through solid materials – such as food items. A radiograph can then be created, allowing you to see into your product and determine anything that shouldn’t be there. It enables you to see the exact location of unwanted items, making their removal easier.

The radiograph image is coloured by density. The less dense an item is, the lighter it will appear in the image, which helps you analyse any oddities. This analysis can also be done in real-time, so you can address the issue before it moves further through production.

You can adapt the diode of your x-ray system to enable you to find more intricate inclusions, which helps x-ray work against a wide range of contaminants and better protect your final product.

It’s also possible to use x-rays to find something missing in your product if your mass level is too low by giving you sight into the product.

X-ray works on packaged products, including food or other items contained in glass jars. Due to this, it can be a helpful form of final inspection, allowing you to check your output before it moves into the hands of your customers.

It will also work for in-line inspection, empowering you to review your products as they move through the line. In this sense, x-ray can be used as a tool across the stages of production, enabling you to get a better return on investment.

What are the benefits?

Many benefits can be unleashed on your product line if you implement x-ray product inspection. We’ve listed some of the most significant advantages below.

Detects a broad range of contaminants

The capability of x-ray means it can be used to safeguard your output against a broad range of contaminants. These include, but are not limited to:

- Glass

- Some metals

- Bone

- Stone

- Salt

- Rubber

- Limestone

Through this, you can cover contamination that may appear from anywhere in the production process, including in your raw materials, from machinery or by user error. This gives an enhanced level of inspection, so you identify a broader scope of potential issues in your product and improve the chances of a flawless final product.

X-ray is also ideal if you work with multiple lines, as it is compatible with most products and will let you identify the contamination that commonly occurs in each product.

It is worth noting that an x-ray cannot detect everything. Some oddities, like hair and some wood, may not be found if they appear in your product, so you may still want to incorporate other quality control practices, such as hygiene guidelines, alongside your x-ray inspection. Regardless, x-ray will still offer a higher level of protection than most other product inspection solutions.

Highly sophisticated detection

X-ray offers advanced detection, enabling you to identify contaminants even when they appear at a minute level. By selecting a suitable diode for your system, you get access to detailed insight into your product, so you find the slightest faults.

Its comprehensive analysis can overcome complex inspection challenges – for example, identifying glass contamination within glass packaging or seeing products in rigid containers. It also enables you to find fragments of bone within fish, distribution of holes in cheese and broken seals in your packaged products.

This means x-ray can remove several barriers in the production process, depending on the unique requirements you need to meet. With this, you address contamination while ensuring better product quality in general.

Safety

Myths still linger around the use of x-ray in food processing, but the reality is it’s completely safe. X-rays utilise radiation (which is often confused with radioactivity). However, the radiation exposure is minimal, with an x-ray only passing through an item for less than a second to get an image. Food also will not absorb x-ray, so there is no lasting impact. In 1999, a WHO study confirmed that x-ray does not affect food’s nutritional value or safety.

Any x-ray machine you install in your plant should have a range of safety features. These include enclosed cabinets and failsafe systems. If you turn off the power to your machine, it should also immediately stop producing x-rays.

On top of this, any plant utilising x-ray must have an appointed Radiation Protection Supervisor who is fully trained with the system and knows how to comply with ionising radiations regulations. You will also have an external Radiation Protection Advisor to support the supervisor.

With these staff and the safety features included in your system, you can be assured that you are using x-ray correctly and without risk to your workplace or output.

Meet compliance guidelines

In the food industry, there are many standards that manufacturers need to meet. Most standards will require you to follow Hazard Analysis and Critical Control Point (HACCP).

Under the HACCP, manufacturers need to accurately identify potential hazards (such as contamination) in their products and take appropriate steps to resolve the issue before it goes to market. Installing x-ray systems at various stages of your production line will enable you to detect hazards at each point, removing faults early on.

Again, the wide variety of items that an x-ray can detect will be advantageous here to safeguard against more hazards.

By utilising effective inspection and quality control through x-ray, you will ensure effective HACCP protocol in your plant. You can then meet a range of guidelines, including GFSI (Global Food Safety Initiative), ISO (International Standards Organization), BRC (British Retail Consortium) and Food Standards. This will boost your reputation as a reliable manufacturer to clients and customers while reducing any repercussions for non-compliance.

Save costs

Although embedding x-ray in your plant can be a significant investment, it saves you money in the long run. We know that poor quality in manufacturing costs, through lost sales, supply chain disruption and negative PR. By implementing practices to improve quality, you will eliminate the risks.

Using x-ray will help you to reduce waste in your plant. By identifying faults early in the process, you can prevent materials from being thrown away due to poor quality. This will reduce giveaways and get you more from your supplies for better cost-efficiency.

You can also prevent wasted energy and staff resources from having to re-run lines, which should facilitate productivity and encourage faster turnaround times.

If you were to release a poor quality or hazardous product onto the market, you are immediately at risk of product recalls. A US study estimated that a food recall costs the average manufacturer $10 million in direct costs – and that’s not accounting for the damage to reputation and long-term sales.

By incorporating x-ray as a comprehensive, effective form of product inspection, you should drastically lower the risk of product recalls and the sizeable cost implications that follow.

Improve the customer experience

Quality control and industry standards aim to prevent consumers from coming into harm. In this sense, one of the most significant benefits of x-ray is that it protects your customers.

If a customer were to experience an issue in your product – such as through injury, illness or allergic reaction – it would result in negative consequences for your business, including complaints, investigations, lawsuits and so on. All of this impacts your costs and reputation, and this can’t always be recovered from. If you work with clients, such as supermarkets, they may end contracts with you due to a scandal, as seen in the 2013 horse meat scandal.

By offering high-quality, safe products, you can improve the customer experience, meeting their expectations. This will allow you to enjoy a consistent reputation as a trusted supplier and secure rising sales as a result.

In summary

X-ray boasts many advantages that make it an ideal choice for food processors. With its capacity to safely identify a wide range of contaminants, solve complex production issues and improve quality, there is no surprise it is becoming increasingly adopted in the industry.

By using it in your quality control process and at various stages of the production line, you can secure what every food manufacturer wants: guaranteed product safety, compliance to industry standards including HACCP, and satisfied clients and customers.

If you are considering installing an x-ray system in your plant, get in touch with Yamato.

We offer advanced x-ray systems designed in line with your production line needs and installed at various points. All our systems come with safety features, providing peace of mind.

We can also offer support with the appointment of your Radiation Protection Supervisor and Advisor, staff training, system maintenance and commissioning.